M&E services are essential components of a warehouse infrastructure that involve installing and maintaining mechanical, electrical, and construction systems. M&E systems play a crucial role in ensuring the functionality, comfort, and safety of the warehouse or building occupants.

They are also known as material handling systems, and are crucial for efficiently moving and storing goods, encompassing equipment like conveyor belts, forklifts, cranes, and automated systems, optimizing inventory management and order fulfillment. These refer to the equipment and systems that control the building’s environment, including heating, ventilation, and air conditioning (HVAC) systems.

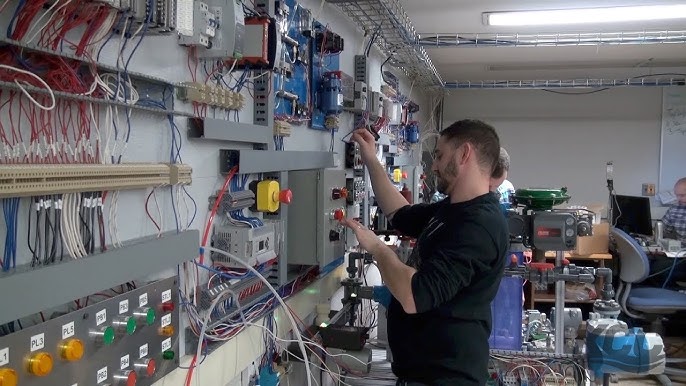

The process of planning, developing, and implementing power systems that distribute electricity safely and efficiently within a building or infrastructure. It encompasses power system planning, equipment selection, energy optimization, and ensuring compliance with safety standards. The components like wiring, circuit breakers, distribution panels, lighting systems, and potentially generators or inverters. A data communication system involves the installation and maintenance of data and communication infrastructure.

These involve designing and building facilities for storage and distribution, often utilizing methods like pre-engineered buildings or tilt-up construction for efficiency. Workings are categorized by materials (steel, concrete, wood-framed, and fabric), methods (conventional, pre-engineered, modular), design (clear span, multilevel, high-bay), and function (cold storage, hazardous material, distribution centers, retail). This system also includes a fire protection system, plumbing, and sanitary system.

Warehouse maintenance is the process of keeping a warehousing facility in optimal functioning condition. It involves performing necessary repairs, keeping machinery and equipment running, and conducting regular inspections, audits, and cleanups to minimize clutter and safety hazards among a few.

Regular warehouse maintenance is crucial for ensuring safe, efficient, and cost-effective operations by extending equipment lifespan, minimizing downtime, and preventing accidents and damage to goods.